FDM (Open Chamber/Filament Material)

Features summary

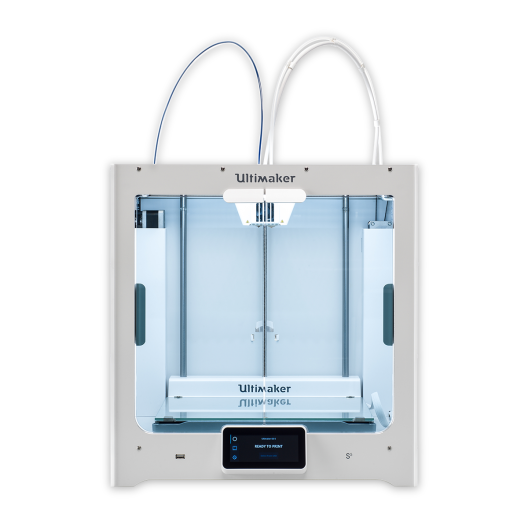

The Ultimaker S5 is built to run continuously and maximize uptime. Its best-in-class technical specifications deliver performance you can rely on. Designed for your success, the Ultimaker S5 is part of the complete Ultimaker 3D printing solution – one trusted by hundreds of thousands of professionals worldwide.

- Large build volume: 330 x 240 x 300 mm (13 x 9.4 x 11.8 inches)

- Compatible with high-strength glass and carbon fiber filament

- Down to 20 micron (0.001 inch) layer resolution

- Open filament system – print with any 2.85 mm material

- 4.7-inch touchscreen interface – Winner of iF Design Award 2019

Enhanced Reliability

Trust the Ultimaker S5 to do its job while you do yours. Its advanced active bed leveling ensures a perfect first layer, glass doors control the airflow, and dual filament flow sensors will pause your print and notify you if you run out of material.

Bigger build volume

A build volume of 330 x 240 x 300 mm (13 x 9.4 x 11.8 inches) gives you more freedom to produce larger designs or print multiple parts on one build plate. So you can meet demand with maximum efficiency, with a 3D printer that fits comfortably on your desk.

Composite-ready

Thanks to our pioneering alliance with global materials companies, Ultimaker S5 offers an easy way to print with the world’s most advanced filaments – including glass and carbon fiber composites.

For non-abrasive filaments, switch between build and support material in seconds, choosing from 0.8, 0.4, or 0.25 mm print cores for fast or detailed prints. To unlock more high-end applications with abrasive materials, select print core CC Red 0.6 (sold separately).

Award-winning touchscreen interface

Winner of a 2019 iF Design Award, the touchscreen interface simplifies every action with the Ultimaker S5. Step-by-step setup, navigation, and maintenance remove the need for training and deliver a hassle-free, intuitive 3D printing experience.